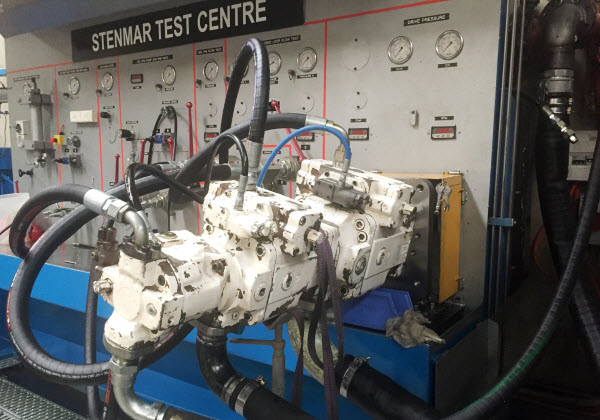

Stenmar Group’s hydraulic overhaul service provides a dependable and cost-effective way to keep your hydraulic equipment in top condition. Our expert engineering team, cutting-edge testing tools and facilities help ensure we extend the lifespan of your hydraulic equipment. Regular hydraulic system maintenance helps you control plant efficiency, productivity and long-term profitability.

Expert hydraulic system maintenance

The Stenmar Group team has decades of hydraulic engineering experience and a vast knowledge of fluid power equipment, technical processes and compliance requirements across sectors including mining, manufacturing, transport, civil and construction.

Our team is skilled in all types of diagnostic, servicing and MRO (maintenance/repair & overhaul). Our comprehensive capability provides you with a one-stop shop for hydraulic scheduled maintenance, troubleshooting, emergency repairs and remanufacture.

We can provide full documentation for hydraulic system certification, including photographic job assessments and failure analysis reports.

Flexible hydraulic service

We offer fast response mobile hydraulic repair, or we can securely transport your equipment back to our hydraulic workshop for full hydraulic overhaul.

We work with you to minimise disruption to your production. Stenmar can schedule work at specific times or after hours to help keep things moving. If needed, we also provide in-house machining and manufacture.

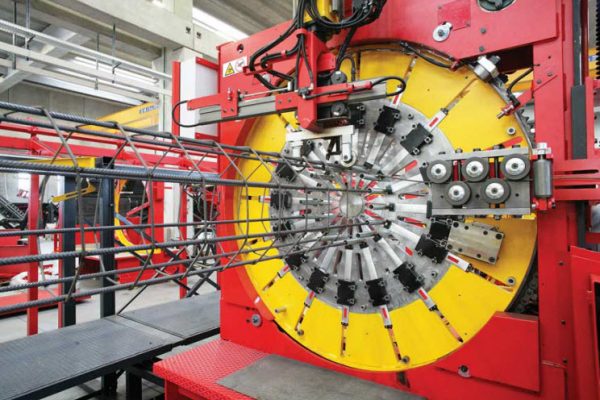

Our comprehensive workshop facilities include:

- 400kw variable speed drive hydraulic test rig

- Controlled environment clean room for contamination-free assembly

- Extensive stock of spares

- Fully resourced technical library

- Large capacity cylinder assembly/strip bench and nut cracker

- Large-scale in-house machining and fabrication capacity

- Oil transfer, diagnostic and flushing equipment

- Paint bay

- Rotational and positional jigs

- Shot blast equipment

- Steam turbo-wash machinery.

We use state-of-the-art testing tools to diagnose any issues and help restore your pumps, cylinders, motors and valves to peak performance.

Hydraulic maintenance services

Our broad range of maintenance services include:

- Equipment inspection

- Filtration consultation

- Flow testing

- Data logging

- Equipment efficiency survey

- Fault analysis

- Fluid condition monitoring

- Hydraulic stocktake

- Data capture in milliseconds

- ISO 4406 cleanliness classification

- Measurement of flow, pressure and temperature in real time

- Pump testing

- Offline filtration and cooling

- Reliability reporting

- Accumulator audit

- System cooling

- Varnish removal

- Moisture removal/dewatering

- Accumulator nitrogen pre-charge

- Real-time oil sampling.

Please contact us for comprehensive and tailored hydraulic servicing for your business.